When it comes to shipping containers, it has never been hip to be square. Cylindrical barrels (aka, drums) have been used for hundreds of years to transport both liquid and dry goods. Originally made of wood, rounded barrels have been the ideal shipping and storage container for a wide range of things from wine, beer, and oil to flour, spices, sugar and even gun powder. With such a long reign as the “standard,” it seems unlikely another other shape will ever unseat the cylinder, but with changes in shipping practices, many are considering the benefits that square drums offer.

Why Steel Drums are Traditionally Cylindrical

When it comes to why the world landed on a cylindrical shipping container for transporting its commercial goods, a lot has to do with naval loading and unloading practices. Back in the infancy of world commerce and international shipping, dock workers would load and unload ships by rolling barrels up a ramp and onto the deck of a ship. Barrels would be stowed below deck until the ship came into port. Because of the rocking and swaying that would occur while at sea, barrel manufacturers did explore the concept of square barrels in the 1850s in order to use space more efficiently and to prevent the barrels from rolling around below deck. And in that regard, square barrels were far superior to their cylindrical counterparts. However, when it came to loading and unloading them, square barrels proved far too labor intensive, adding significant time for each barrel to be hand-carried, rather than rolled.

When it comes to why the world landed on a cylindrical shipping container for transporting its commercial goods, a lot has to do with naval loading and unloading practices. Back in the infancy of world commerce and international shipping, dock workers would load and unload ships by rolling barrels up a ramp and onto the deck of a ship. Barrels would be stowed below deck until the ship came into port. Because of the rocking and swaying that would occur while at sea, barrel manufacturers did explore the concept of square barrels in the 1850s in order to use space more efficiently and to prevent the barrels from rolling around below deck. And in that regard, square barrels were far superior to their cylindrical counterparts. However, when it came to loading and unloading them, square barrels proved far too labor intensive, adding significant time for each barrel to be hand-carried, rather than rolled.

With today’s modernization of shipping practices, however, a square barrel is once again making a growing appearance. Ships these days are not loaded by dock workers rolling and carrying individual barrels. Instead, they are loaded by cranes lifting truck-sized intermodal containers, often filled to capacity with goods on pallets. The intermodal containers are square, the pallets are square, and much of the ship’s design is also square. So in today’s shipping world, squares are actually claiming the reigns.

So how can a simple change from cylindrical to square provide such a big improvement on a classic design?

Larger Capacity with the Same Footprint

A standard 48×48 pallet is able to comfortably, and safely, accommodate four 55-gallon drums. Because some square drums have the same footprint as a standard 55-gallon drum, that same pallet will be able to comfortably and safely accommodate four of our 71-gallon SquareL drums. The result is a 29% increase in the shipping capacity of each pallet. Effectively, by using square drums, rather than the standard cylinder, one pallet is able to transport slightly more than the equivalent of five 55-gallon drums. To put this is practical use, if a shipment contains twelve 71-gallon square drums, the shipper is effectively transporting four standard pallets worth of material, for the price of three.

A standard 48×48 pallet is able to comfortably, and safely, accommodate four 55-gallon drums. Because some square drums have the same footprint as a standard 55-gallon drum, that same pallet will be able to comfortably and safely accommodate four of our 71-gallon SquareL drums. The result is a 29% increase in the shipping capacity of each pallet. Effectively, by using square drums, rather than the standard cylinder, one pallet is able to transport slightly more than the equivalent of five 55-gallon drums. To put this is practical use, if a shipment contains twelve 71-gallon square drums, the shipper is effectively transporting four standard pallets worth of material, for the price of three.

Square Drums Ship for Less

With a capacity 29% larger than a cylindrical drum, a square drum will offer savings on shipping and storage costs. Because shipping four 71-gallon square drums is the equivalent of shipping slightly more than five 55-gallon drums, shipping costs for any liquid or dry goods are easily reduced by at least 25%. Many carriers charge a flat rate per pallet, so long as the weight does not exceed certain limits, and the weight increase caused by the larger capacity of square drums is not typically substantial enough to warrant an increase in price. Effectively, square drums allow a shipper to transport substantially more product for the same price.

Square Drums Offer More Efficient Storage

Even observing best practices for safe storage, cylindrical drums take up 4 square feet of floor space, despite only having a footprint of 3.14 sq. ft. In storage, cylindrical drums are surrounded by nearly a square foot of “dead,” unusable space. By taking full advantage of the footprint, without the “dead” space surrounding the cylinder, a square storage drum allows for more efficient and tidier use of space while in storage, which can mean the different between a disorderly, cramped stock room and a tidy one with more usable floorspace. In practice, that means if you have to store 100 55-gallon drums worth of goods, you would need 400 sq. ft. of storage space. That same amount of product, however, could be stored using 71-gallon SquareL drums in 312 sq. ft. Not only is less space needed, but the drums fit snuggly next to each other, making for a neater space too.

Even observing best practices for safe storage, cylindrical drums take up 4 square feet of floor space, despite only having a footprint of 3.14 sq. ft. In storage, cylindrical drums are surrounded by nearly a square foot of “dead,” unusable space. By taking full advantage of the footprint, without the “dead” space surrounding the cylinder, a square storage drum allows for more efficient and tidier use of space while in storage, which can mean the different between a disorderly, cramped stock room and a tidy one with more usable floorspace. In practice, that means if you have to store 100 55-gallon drums worth of goods, you would need 400 sq. ft. of storage space. That same amount of product, however, could be stored using 71-gallon SquareL drums in 312 sq. ft. Not only is less space needed, but the drums fit snuggly next to each other, making for a neater space too.

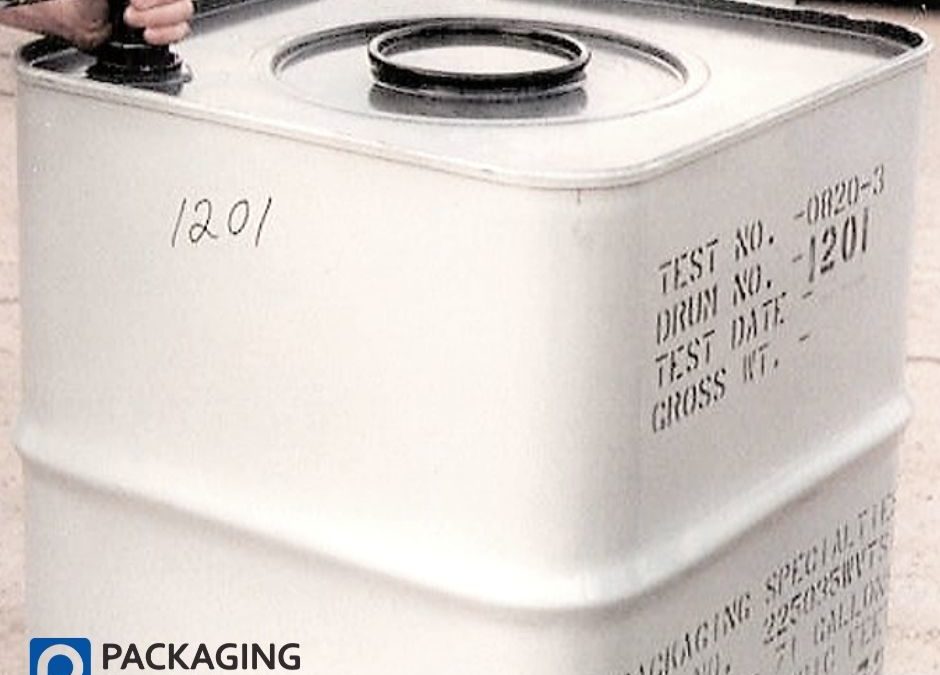

Packaging Specialties offers a 71-gallon SquareL that delivers the best of both worlds, the space efficiency of a square design with all the strength of steel. Contact us today to see just how hip it is to be square.

Related Articles:

The Best Chemical Storage Practices

Recent Comments