You have undoubtedly seen what is commonly referred to as the “fire diamond” on containers being transported as you’ve traveled the Interstate or made your way around town. Officially known as the NFPA 704 labeling system, these fire diamonds provide invaluable information to first responders, but most people are not aware why this labeling system exists or what the different markings even mean. Deciphering the fire diamond will not only clue you in to the purpose and meaning behind the label but will also provide information that just may save your life someday.

What is the “Fire Diamond”?

First developed by the National Fire Protection Association in 1957, the NFPA 704 labeling system (aka, the “fire diamond”) identifies hazardous materials. Often seen displayed on containers or buildings containing hazardous materials, the fire diamond provides information to police, fire fighters, and paramedics who are responding to an emergency involving a hazardous material. The diamond alerts first responders to special equipment they may need to use – such as respiratory protectors or hazmat suits – or precautions they may need to take while responding to an emergency. Although developed for use by first responders, the fire diamond is also useful in everyday working conditions. Chemical storage is often organized according to the NFPA 704 labeling system as well as OSHA’s HazCom 2012 labeling system, ensuring reactive chemicals are not stored near each other in case of a spill.

Fire Diamond Sections and Markings

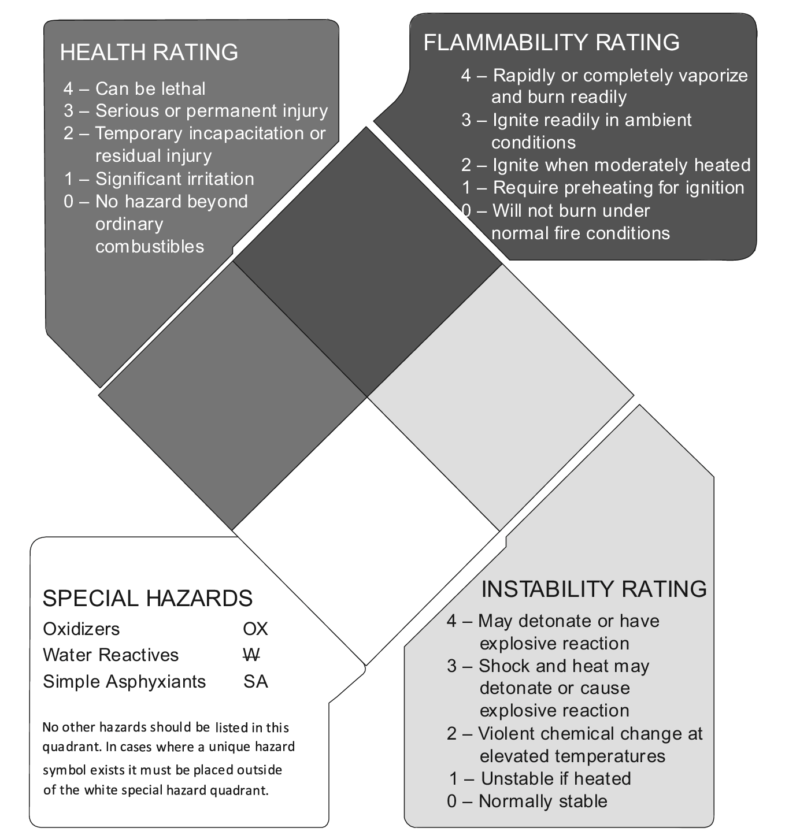

The NFPA 704 label is divided into four sections, each indicating a separate rating for health, flammability, and instability hazards of the chemical contained within. Each section of the fire diamond provides a rating on the degree of severity, on a scale from 0-4. A zero rating tells the responders that the chemical is not hazardous for that category, while a 4 rating is severely hazardous (lethal, extremely flammable, and explosive). The left section always indicates the chemical’s health hazard, displayed in a blue diamond. The top section indicates the flammability hazard, in a red diamond. The last colored section, a yellow diamond on the right, indicates the content’s instability hazard level. The white diamond at the bottom is reserved for special hazard markings, most of which reveal how reactive the chemical is and any special precautions that must be taken when handling it. The bottom section will tell first responders whether a chemical is alkaline or acidic, corrosive or oxidizing, or if it’s radioactive. It can also provide information about how the chemical reacts with water, which is especially important when responding to a fire, or how noxious the gases from the chemical are.

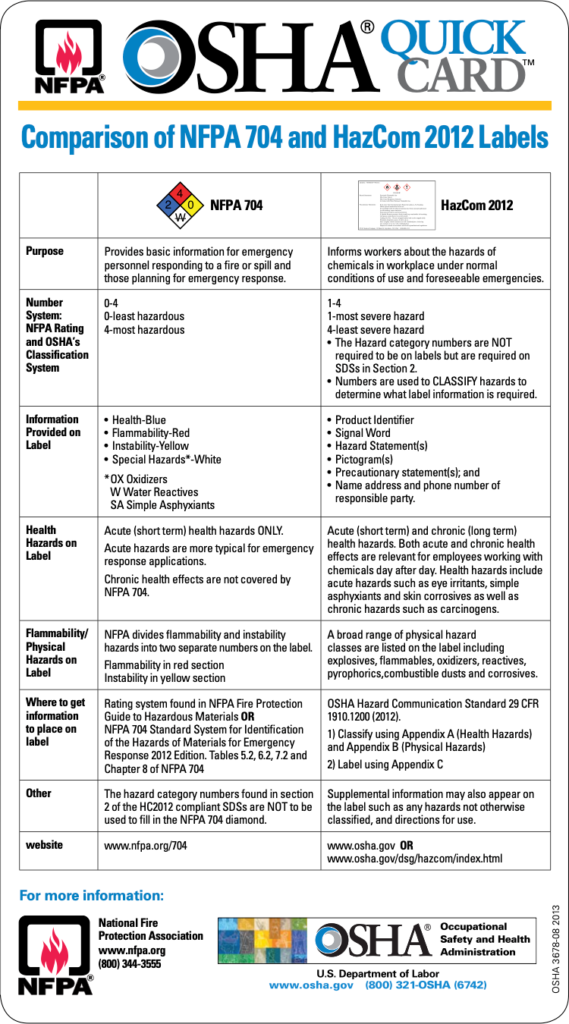

NFPA 704 v. HazCom 2012 Labels

First responders are trained on procedure related to the NFPA 704 label, which is designed to provide critical information in emergency situations. The HazCom 2012 label has been designed by OSHA to provide information for workers about the hazards of a chemical under normal workplace conditions. The markings on the fire diamond have drastically different meanings from those found on HazCom 2012 labels required by OSHA. For example, while a rating of 1 on the fire diamond indicates a minimal hazard, it indicates the most severe hazard on a HazCom 2012 label. The fire diamond is supposed to be displayed on buildings that manufacture, process, use, or store hazardous materials, posted on the exterior of the building, as well as in rooms containing the hazardous materials. Though the NFPA 704 labeling system does not apply to transportation, the fire diamond will often be seen on containers being transported as well as on the actual vehicles transporting hazardous chemicals. Along with the Department of Transportation, the Pipeline and Hazardous Materials Safety Administration has separate standards for labeling hazardous materials during transportation.

For more than 61 years, Packaging Specialties has been providing specialty containers, including those designed to hold and transport hazardous materials. We always remind our customers to ensure their packaging is compliant with all state, federal, and international regulations, as appropriate. Contact us today to see how we can meet your packaging needs!

Related Articles

The Best Chemical Storage Practices

Hazmat Transportation 101: A Brief History

Recent Comments